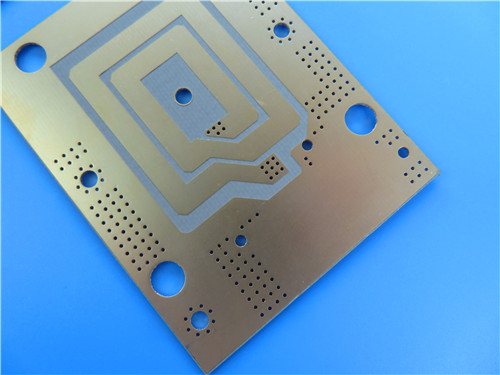

RF-35 2-Layer PCB Optimal Solution for RF and Microwave Circuits

1.Product Introduction

Taconic's RF-35 organic-ceramic laminate combines woven glass reinforcement with advanced ceramic fill technology to deliver exceptional high-frequency performance. This cost-effective 2-layer PCB material features excellent peel strength, ultra-low moisture absorption, and minimal phase shift - making it ideal for commercial microwave applications requiring reliable signal integrity.

2.Key Technical Features

Stable Dielectric Properties:

Dk: 3.5 @1.9GHz

Df: 0.0018 @1.9GHz

Robust Construction:

41kV dielectric breakdown

UL-94 V0 flammability rating

Dimensional Stability:

CTE: 19/24/64 ppm/°C (X/Y/Z)

3.PCB Construction Specifications

| Specification | Value |

|---|---|

| Base Material | RF-35 |

| Layer Count | 2 |

| Board Dimensions | 239.5mm × 130mm (±0.15mm) |

| Trace/Space | 5/7 mils |

| Min Hole Size | 0.3mm |

| Board Thickness | 0.6mm |

| Copper Weight | 1oz (outer layers) |

| Via Plating | 25 μm |

| Surface Finish | ENIG |

| Silkscreen | None |

| Solder Mask | None |

| Electrical Test | 100% tested |

4. PCB Stackup: 2-layer rigid PCB

Copper_layer_1 - 35 μm

RF-35 Core - 20mil (0.508 mm)

Copper_layer_2 - 35 μm

5.PCB Statistics:

Components: 18

Total Pads: 98

Thru Hole Pads: 72

Top SMT Pads: 26

Bottom SMT Pads: 0

Vias: 32

Nets: 2

6.Performance Advantages

Cost-competitive alternative for RF designs

Enhanced copper adhesion for rework capability

Superior high-frequency signal integrity

Compatible with standard PCB processes

7.Primary Applications

Cellular infrastructure power amplifiers

Microwave filter networks

RF couplers and passive components

Wireless communication systems

8.Quality Assurance

IPC-Class 2 standards compliance

100% electrical testing

Global manufacturing availability